Tanning process in leather industry

Florence is well known as the birthplace of Renaissance art and humanist thinking but it was the economic power it wielded that made it possible for culture to flourish. At the foundations of the city’s economic success lay the “Arti” that worked kind of like unions in protecting workers and the trade secrets that would make Florentine craftsmanship (especially fabrics and leather) known throughout Europe. The Arte dei Cuoiai, or the leather-workers guild, was created in 1282 but it wasn’t until the more recent centuries that leather began to take a centre stage as one of the items that embody Italian craftsmanship and design. Today we want to speak about this, especially about the art of tanning (leather). We want to focus on how florentines manage these techniques and how they transform the raw hide into what is known as leather.

Tanning process in leather industry

According with Wikipedia “Tanning is the process of treating skins and hides of animals to produce leather. A tannery is the place where the skins are processed.”

Tanning hide into leather involves a process which permanently alters the protein structure of skin, making it more durable and less susceptible to decomposition, and colouring.

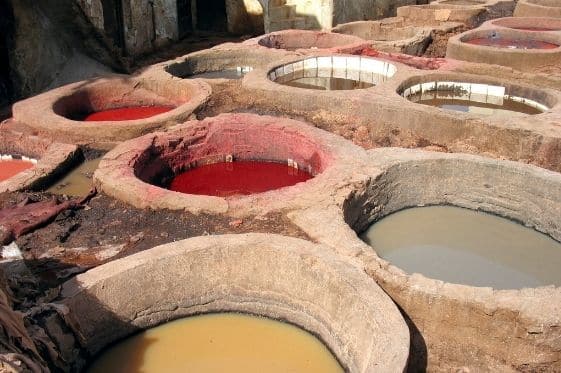

Before tanning, the skins are dehaired, degreased, desalted, and soaked in water over a period of six hours to two days. Historically this process was considered a noxious or “odoriferous trade” and relegated to the outskirts of town.

Historically, tanning used tannin, an acidic chemical compound from which the tanning process draws its name, derived from the bark of certain trees. An alternative method, developed in the 1800s, is chrome tanning, where chromium salts are used instead of natural tannins.

The tanning process in the leather industry

What tanning process did the leather go through?

Tanning is the most important part of the leather making process. It transforms the raw hide into what is known as leather. This process stabilises the leather so it can’t decompose, soak up water or shrink. There are two main ways to do this.

- Chrome Tanning / mineral tanning: Processing the hide in a mix of acids, chemicals, and salts. This can take 3-24 hours. Most of the leather around the world has undergone chrome tanning.

- Vegetable Tanning: This can also be called natural leather or bio leather (although these terms are kind of thrown around to mean whatever the seller wants). This is the traditional tanning method that soaks the hides in vats of water mixed with natural vegetable solutions made from the bark, roots and leaves of numerous plant sources such as oak, spruce, chestnut, mimosa, and many others. This process takes many weeks. This is the closest to the traditional tanning methods and the best for the environment.

Our infallible method has been handed down for centuries, which is why Florentine art is now known throughout the world and together with its products. Buying genuine leather accessories means giving value to tradition. Come and visit our online store.